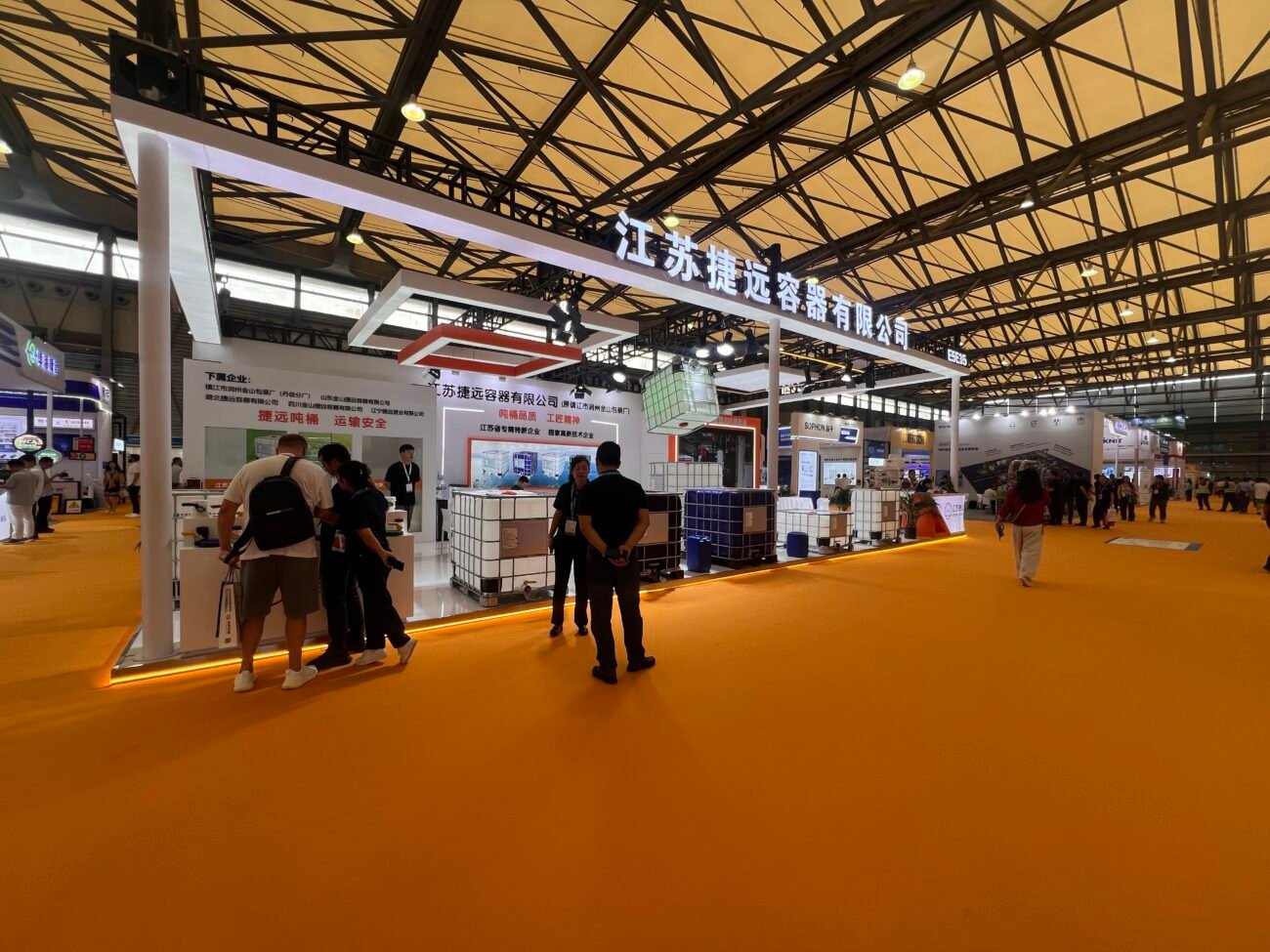

At the forefront of industrial packaging, our company, JieYuan Packaging, has established itself as a leader in IBC manufacturing, setting new industry standards in quality, precision, and efficiency. With our state-of-the-art assembly lines, advanced automation, and a commitment to excellence, we continue to push the boundaries of what’s possible in industrial bulk container production.

Precision Engineering with Advanced Equipment

1

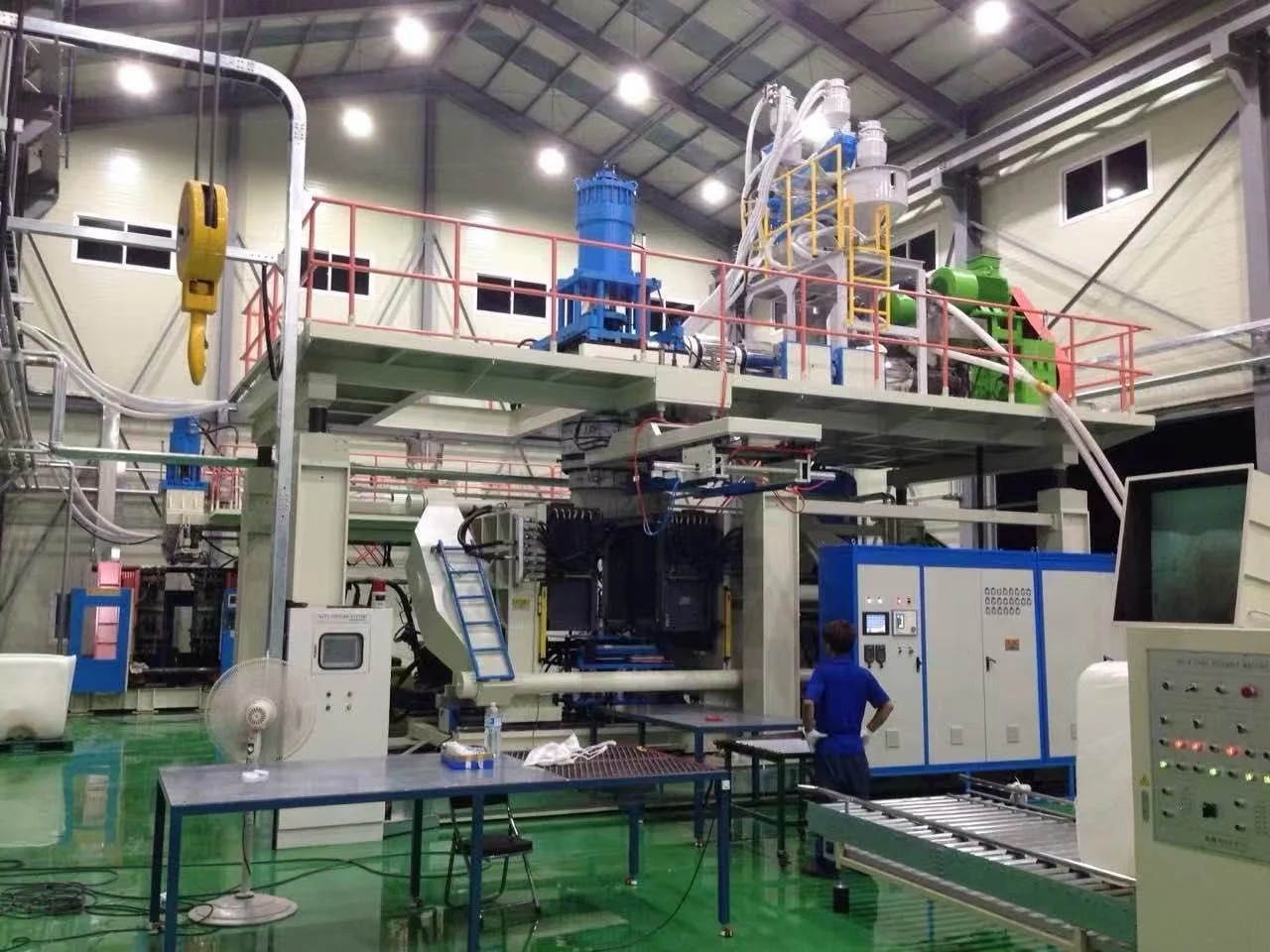

Large-Scale Blow Molding Machines

Our large-scale blow molding machines operate in a 100,000-class cleanroom, ensuring a dust-free, contamination-free environment for the production of high-quality IBC containers. Whether manufacturing for general goods or hazardous materials, we maintain strict quality control to meet regulatory standards and guarantee reliability.

Large-Scale Blowing Machine operated in 100,000-class cleanroom

Large-Scale Blow Molding Machine for IBCs Used in General and Hazardous Goods Applications

2

Automated Bending Machines for High-Precision Frames

An essential component of IBC containers is the metal frame that provides structural integrity. Our fully automated bending machines produce frame components with unmatched precision, ensuring a secure, durable container for transport and storage.

Automated Bending Machine

Seamless Integration of Fully Automated Assembly Lines

3

Automated Frame Production Lines

We operate multiple fully automated frame production lines, each designed to optimize efficiency while maintaining stringent quality control. These high-tech systems ensure:

- Consistent and uniform frame welding and assembly

- Increased production capacitywithout compromising structural integrity

- Enhanced durabilityof IBC cages for long-term use

Automated Frame Production Line 1

Automated Frame Production Line 2

Automated Frame Production Line 3

Automated Frame Production Line 4

Why Our IBC Containers Stand Out?

- Superior Safety & Durability: Our high-precision bending and welding techniquesensure robust, long-lasting containers suitable for hazardous and non-hazardous materials.

- Unrivaled Manufacturing Efficiency:Automation significantly reduces manual errors, increasing productivity and ensuring high repeatability in production.

- Industry-Leading Innovation: We continually invest inadvanced production technologies, ensuring our customers receive top-tier IBC solutions.

Leading the Future of Industrial Packaging

With a dedicated R&D team and a relentless pursuit of innovation, we are shaping the future of IBC manufacturing. Our cutting-edge assembly line and unparalleled industry expertise set us apart, delivering quality, reliability, and performance that customers can trust.

Looking for IBC Solutions? Contact Us Today!

If you need high-quality IBC containers or are looking for IBC manufacturing solutions, including machine sourcing, automation consulting, or production setup, we are here to help!

Contact us today to discuss your needs and explore how we can support your business with the best IBC solutions in the industry.

Leave a comment